Among the many underwear production processes, the most common manufacturing processes are hot pressing and traditional sewing. The choice of process directly affects all dimensions of the product, such as comfort, durability, and production efficiency, which is the most concerned by buyers. In this article, I will comprehensively analyze the advantages and disadvantages of the two to help you choose the process that best suits your brand positioning.

What is the heat pressing process in underwear manufacturing?

The hot pressing process is also called thermal bonding. This process is most common in seamless bras and seamless underwear. Unlike the traditional sewing process, it uses high temperature and high pressure to bond the fabrics together, and the finished product presents a seamless effect.

The advantages of this process: it is truly invisible, leaving no so-called sewing lines, and reducing irritation to the skin. The production efficiency is also high because the steps of manual sewing are reduced, which greatly saves the production cycle.

Disadvantages: It is not suitable for bra designs with complex structures, and the investment cost of hot pressing equipment is relatively high. The requirements for fabrics are also high, requiring materials that are resistant to high temperatures, high pressures, and good ductility.

What is traditional sewing?

Cutting multiple pieces, sewing the fabrics together with needle and thread on a sewing machine to build the bra structure. In bra production, traditional sewing is the most basic process and the longest-used process. It also plays a very important role in clothing manufacturing.

Advantages of this process: The bra has better support performance. It is more flexible and can produce bras with complex structures, such as steel rings, side supports, lace, embroidery, etc. The equipment cost is cheaper than hot pressing equipment.

Disadvantages: Due to the traditional sewing process, the seams are obvious and can be easily seen when wearing tight clothes, which cannot be completely avoided. The production efficiency is low, there are many processes, and it takes a long time.

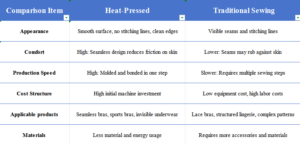

Hot Pressing VS Traditional Sewing

How are brands chosen?

We need to choose the kind of process according to our own brand positioning has been the target users to decide.

If your target users are young market, pursuing high comfort, invisible wearing feeling, then the heat pressing process is the most suitable for your needs.

If your target users are looking for functionality, high support, high load bearing, traditional sewing process has this advantage.

Conclusion:

Heat pressing and traditional sewing processes have their own advantages, and it’s mostly about whether they fit your brand’s positioning.

If you’re looking for a lingerie supplier who is skilled in both processes, we have over 20 years of experience in lingerie manufacturing with two complete production lines for both heat pressing and sewing, so please feel free to contact us and help your brand grow.

FAQ

Is seamless lingerie a complete replacement for traditional underwear?

No, while seamless underwear is more comfortable, it is slightly less supportive. The traditional sewing process is able to satisfy (large cups, breastfeeding, shaping). Therefore, the two will coexist for a long time, each catering to a different market segment.