Today, I will introduce you to the fibers widely used in the underwear textile industry.

Most fabrics are woven from yarns, and yarns are made of fibers. Therefore, fibers are the core of the fashion apparel industry, and they give products many characteristics. For brands, buyers, and designers, understanding and choosing the right fibers directly affects the comfort, elasticity, breathability, support and durability of products.

what is textile fibers

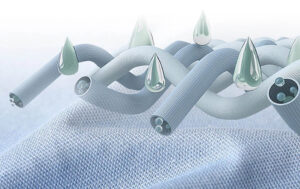

Textile fiber is the smallest component that makes up a fabric.

It is a thin, soft, thread-like material.

Different types of fibers give fabrics different properties and feel, such as elasticity, softness, breathability and durability.

Therefore, understanding fibers will help you more accurately incorporate the right fabric into your underwear or clothing collection when designing and selecting materials.

textile Fibre Classification

It is roughly divided into two categories: natural fiber and chemical fiber

Natural fiber is divided into plant fiber and animal fiber

Natural fiber comes from plants and animals in nature and usually has good skin affinity and moisture absorption. In the clothing industry, the most common ones are cotton, wool and silk.

Plant fiber: coconut shell fiber, cotton, hemp, flax, jute, ramie, raffia, etc.

Animal fiber: wool, cashmere, silk, camel hair, etc.

Chemical fibers are divided into recycled fibers and synthetic fibers.

Recycled fibers and synthetic fibers are both man-made. The only difference is that synthetic fibers are made from 100% petrochemical raw materials, while recycled fibers are made from natural materials (usually cellulose extracted from wood) with chemicals added.

Recycled fibers: viscose, modal, tencel, etc.

Synthetic fibers: polyester, nylon, spandex, lycra, polypropylene, polyethylene, etc.

Plant fiber

They come from the natural fibers extracted from the seeds, leaves or stems of plants in the nature we live in.

In underwear clothing or other textile industries, the most widely used natural textile fiber is cotton.

Cotton

Plant origin, derived from the surface of plant seeds.

It has good durability, moisture absorption and skin-friendliness, and is widely used in the production of cotton bras, cotton underwear, baby clothes, home clothes and other intimate lingerie fabrics. Cotton is considered one of the best fabrics for underwear manufacturing, especially for breathable and skin-friendly lingerie.

Cotton fibers tend to shrink after washing. In order to reduce or avoid shrinkage problems, underwear factories will use “pre-shrinking treatment” to improve fabric stability and reduce changes after washing.

Animal fiber

Animal fiber is a natural protein fiber derived from the surface of animals. Its main components are keratin (wool) or silk protein (silk). It has good warmth retention, moisture absorption and comfort, so it is often used in high-end intimate clothing, such as bra cup linings, pajamas, etc.

Silk

It comes from the secretions of silkworms, which form filaments after hardening.

The fiber is very fine, very smooth, and very beautiful in color. It is one of the most luxurious natural fibers.

In the textile industry, it is often used to produce luxury silk lingerie, bridal bras, and premium nightwear because this silk lingerie fabric is relatively expensive.

Silk bras have a high-end luster and are light and soft to wear.

Silk is completely biodegradable and is an environmentally friendly sustainable material. It is particularly suitable for lingerie brands or high-end intimate product series that advocate environmental protection concepts.

Wool

A natural animal fiber made from sheep wool after shearing, washing and spinning.

Wool is a temperature-regulating material with excellent elasticity, warmth retention and moisture absorption. Underwear manufacturers often use it to make thermal underwear and autumn and winter underwear.

This curly fiber structure can lock air and form a natural insulation layer, which can keep the body temperature stable even in cold environments.

It is recommended to use Merino wool, which is softer and more delicate, and is not easy to cause skin itching.

In addition, wool also has the advantages of natural antibacterial, deodorizing and antistatic properties.

Regenerated fiber

This fiber is made from cellulose extracted from natural materials and chemically treated to create an artificial fiber that retains the skin-friendly properties of natural fibers while giving them better properties through artificial processes.

Viscose

The earliest man-made fiber is viscose fiber, which was invented by British Charles Frederick Cross, Edward John Bevan and Clayton Beadle in 1891 and patented in 1892.

Rayon/viscose fiber is made of cellulose in natural plants through chemical treatment and re-spinning.

The feel of cotton and the gloss on the surface provide a luxurious effect, making it a cheap substitute for silk.

It has a very strong moisture absorption capacity and good breathability, making it drier and more comfortable to wear.

It is used in the production of underwear, has good dyeing performance, is easy to color, and is suitable for various designs.

Modal

Modal is made by spinning cellulose extracted from natural wood pulp through an environmentally friendly process. It is an optimized and upgraded version of traditional viscose fiber.

It is one of the environmentally friendly fibers. The raw materials come from sustainable forestry, and the production process has low water consumption and less pollution.

Modal fiber combines the natural skin-friendliness of cotton with the smooth feel of silk, making it an eco-friendly lingerie fabric choice for brands focusing on sustainability. It is widely applied in modal underwear, modal bras, and sustainable lingerie collections.

Synthetic fiber

It is a completely artificial fiber, which is made from a polymer formed by artificial polymerization of chemical raw materials such as petroleum and natural gas, and then manufactured through processes such as melt spinning or solution spinning.

It is different from natural fibers and regenerated fibers, does not rely on natural plants or animal materials, and is a type of fiber made entirely by chemical methods.

Nylon

Nylon, also known as polyamide fiber, was first developed by DuPont in the United States in 1935.

Polyamide is generated through chemical polymerization and then melt-spun into fibers.

As one of the most wear-resistant textile fibers, it not only has excellent strength and elasticity, but also has the advantages of softness, lightness, quick drying and easy dyeing, making it one of the most common synthetic fibers in underwear, especially for sports bras, seamless bras, and durable lingerie fabrics.

With the advancement of technology, more excellent variants have gradually emerged, including nylon 6, nylon 66, and superfine nylon.

Polyester

Polyester fiber is often used in the production of seamless underwear, sports underwear, and home clothes. Especially after adding spandex material, the product will have better elasticity and fit.

It has excellent tensile resistance, wear resistance, quick drying, and chemical resistance.

At the same time, this fabric is wrinkle-resistant and not easy to deform after washing.

Conclusion

Fiber is the most basic and critical raw material in Bra manufacturer. A deep understanding of various types of textile fibers will help you make more accurate decisions in the material selection stage, while establishing product advantages in functionality, comfort, cost control and brand concept.

As a professional underwear manufacturer, we provide a wide range of fabric solutions including natural, recycled and synthetic fibers. Welcome to contact us to work together to create high-quality underwear products that are both fashionable, functional and environmentally friendly.

FAQ

what provides more textile fibers than animals or minerals?

Among all sources of textile fibers, plants are the most abundant source.

Plant fibers (such as cotton, flax, hemp, jute, etc.) are widely available and have high yields. In contrast, animal fibers (such as wool, silk, cashmere) have limited yields and high costs.